User Scenarios¶

EnOS provides a series of Industry Application Common Building Blocks (CBBs) that application developers can leverage to quickly build applications, lower the development barrier, and improve efficiency. This article uses typical business scenarios to demonstrate how to design solutions using CBBs and explains when to choose a specific CBB.

Scenario 1: Real-Time Asset Monitoring of New Energy Power Plants¶

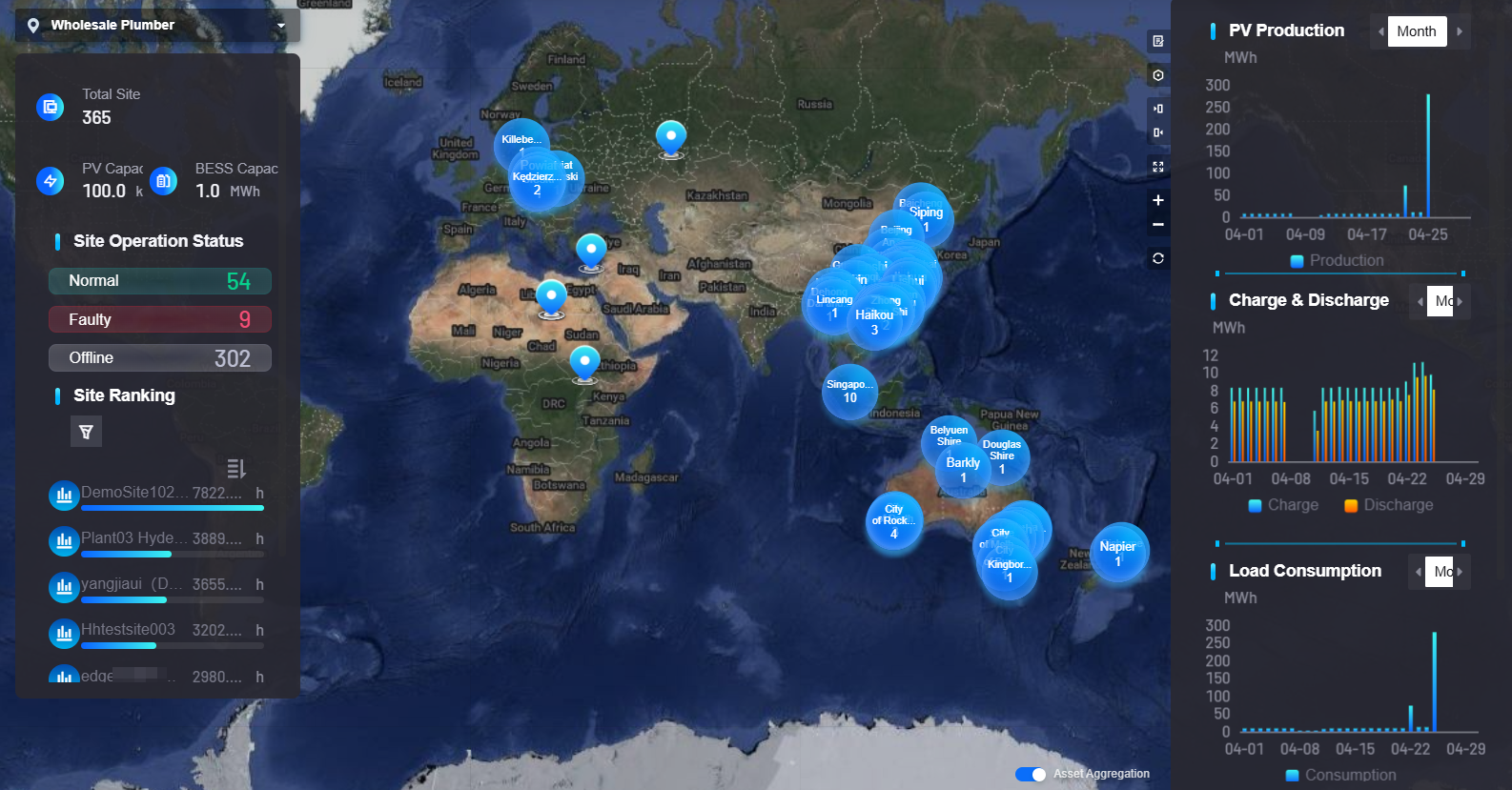

Business Requirements: A new energy company needs to monitor the operating status of distributed solar power plants, providing real-time visibility into device performance, power generation, and potential faults, and quickly respond to abnormalities.

Challenges:

Cross-regional, multi-device data visualization.

Rapid identification of abnormalities and notifications to the operations team.

Business personnel need to build monitoring dashboards without code.

CBB Solution:

Unified Monitoring: Builds a cross-domain asset monitoring page that displays device status, measurement point data (such as power generation and voltage), and key metrics. Business personnel can quickly configure site lists and device details pages using templates to monitor power plants in multiple regions in real time. For more information, see EnOS Unified Monitoring.

Digital Twin Visualization: Supports drag-and-drop configuration of custom dashboards, integrating data from multiple sources (such as device measurement points and weather data) to display the dynamic operating status of the power plant. For example, create a 3D digital twin view to display device statistics and real-time data. For more information, see EnOS Digital Twin Visualization.

Alarm Management: Configure alarm rules (such as “Inverter temperature exceeds 60°C”) to generate alarms of different levels (such as “Warning” or “Fault”). Notifications are automatically triggered to ensure timely handling of anomalies. For more information, see EnOS Alarm Management.

Application Portal: Provides a unified entry point, integrating all monitoring pages and alarm information, ensuring users can access applications through a single platform and simplifying permission management and operation processes. For more information, see EnOS Application Portal.

Why Choose These CBBs:

Unified Monitoring: Suitable for rapid deployment of standardized asset monitoring templates to meet cross-domain requirements.

Digital Twin Visualization: Suitable for visualization scenarios requiring high customization.

Alarm Management: Ensures automated anomaly detection and handling.

Application Portal: Provides a consistent user experience and permission control.

Scenario 2: Energy and Carbon Emission Management in a Smart City¶

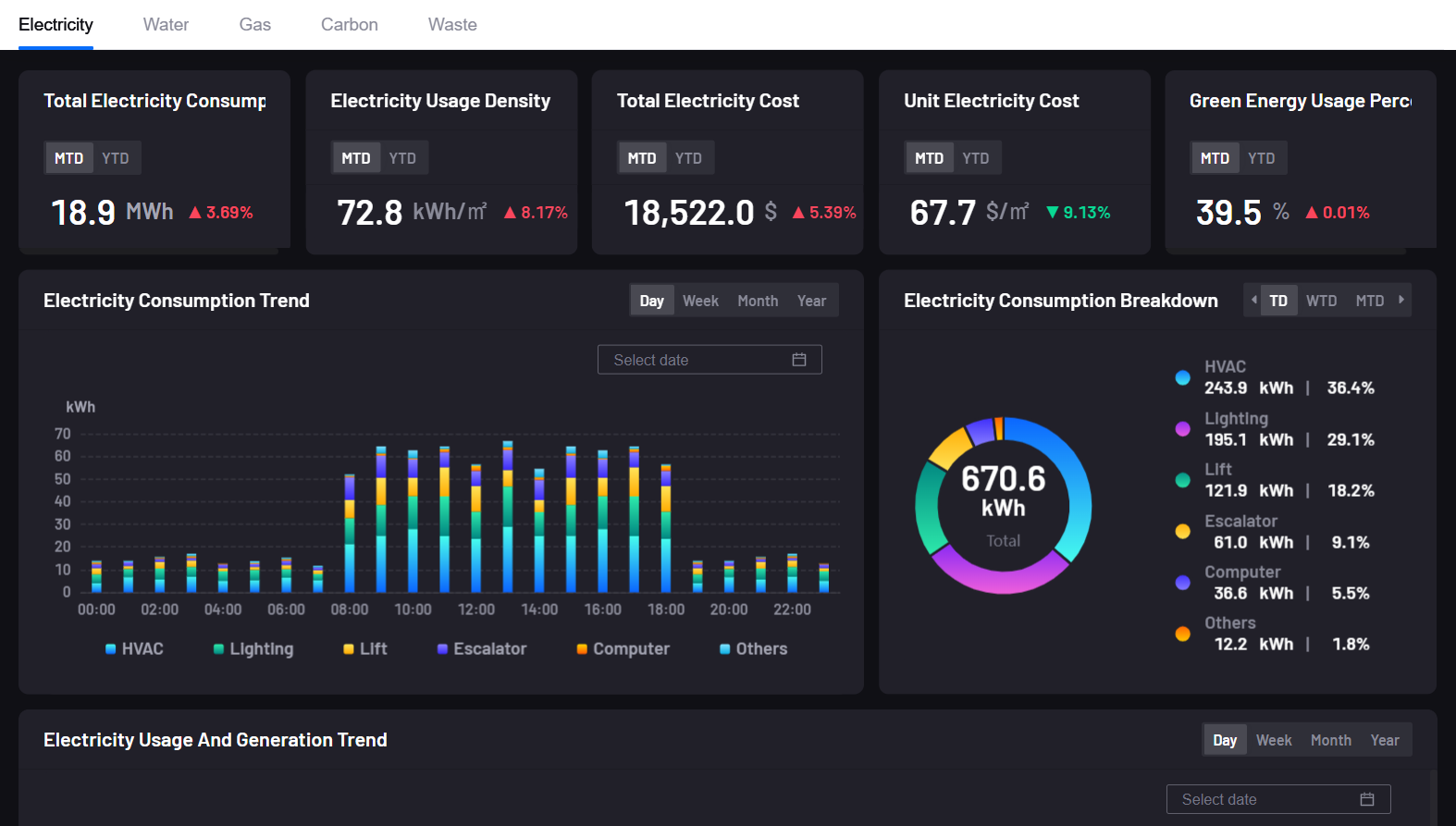

Business Requirements: A city management department needs to monitor regional energy consumption and carbon emissions, generate KPI reports, and push energy-saving notifications to the department.

Challenges:

Requires integration of multi-source data (such as water, electricity, carbon, and energy consumption data) for analysis.

Requires definition of standard KPIs and generation of periodic reports.

CBB Solution:

Unified Monitoring: Configures a cross-domain monitoring dashboard to display regional energy consumption and carbon emissions data, supporting multi-site comparative analysis. For more information, see EnOS Unified Monitoring.

Reporting Tool: Designs carbon emissions and energy usage reports, generating monthly or annual reports based on templates to meet regulatory requirements. For more information, see EnOS Reporting Tool.

Digital Twin Visualization: Builds a city energy management dashboard, displaying real-time KPIs and trends to aid decision-making. For more information, see EnOS Digital Twin Visualization.

Application Portal: Provides a unified access portal, manages employee and administrator permissions, and ensures data security. For more information, see EnOS Application Portal.

Why Choose These CBBs:

Unified Monitoring Suitable for multi-source data integration and cross-domain monitoring.

Reporting Tool Meet standardized and customized reporting needs.

Digital Twin Visualization Provides high-level data insights.

Application Portal Ensures permission management and user experience.

Scenario 3: Equipment Maintenance and Work Order Management in Manufacturing¶

Business Requirements: A manufacturing company wants to optimize its equipment maintenance process, track maintenance tasks through a work order system, and generate periodic equipment performance reports.

Challenges:

Requires automated maintenance task assignment and progress tracking.

Requires customized reports to analyze equipment operating trends.

Requires non-technical personnel to participate in report design.

CBB Solution:

Work Management: Automates the generation and assignment of maintenance work orders, tracking task status (e.g., “pending” or “completed”). Supports integration with third-party CMMSs for optimized collaboration. For more information, see EnOS Work Management.

Alarm Management: Monitors equipment anomalies (e.g., “vibration exceeds standard”) and triggers maintenance work orders. For example, when a sensor detects an anomaly, a work order is automatically created and assigned to the nearest engineer. For more information, see EnOS Alarm Management.

Reporting Tool: Business personnel use code-free templates to design equipment performance reports that display metrics such as uptime and fault frequency. Export to PDF or Excel is supported to meet cross-departmental needs. For more information, see EnOS Reporting Tool.

Digital Twin Visualization: Creates dashboards showing equipment operation trends, displaying historical data and predicting maintenance needs, and assisting in decision-making. For more information, see EnOS Digital Twin Visualization.

Application Portal: Centrally manages access rights for work orders and reports, ensuring that users from different departments can access relevant functions. For more information, see EnOS Application Portal.

Why Choose These CBBs:

Work Management Streamlines the work order process, ideal for task-driven maintenance scenarios.

Alarm Management Connects equipment monitoring and maintenance actions.

Reporting Tool Meets the customized reporting needs of non-technical personnel.

Digital Twin Visualization Provides intuitive trend analysis.

Application Portal ensures secure permissions and convenient operation.